Nickel strip belt, a critical component in lithium-ion battery modules, undergoes a precise and multi-stage manufacturing process to ensure high conductivity, strength, and corrosion resistance. Its production is vital for creating reliable electrical connections between individual battery cells. The transformation from raw material to finished product involves several meticulous steps, which can be distilled into three key phases.

Material Selection and Preparation

The process begins with the selection of high-purity raw materials. The primary material is nickel, often alloyed with small amounts of other elements like magnesium or tin to enhance specific properties such as strength or oxidation resistance. The chosen material is melted in a furnace and cast into large ingots. These ingots are then heated and hot-rolled into thinner strips, initiating the formation of the belt's basic profile and beginning the refinement of its internal grain structure.

Precision Rolling and Annealing

This phase is crucial for achieving the exact mechanical and electrical properties required. The strip undergoes a series of cold rolling processes, where it is passed through successive sets of rollers to reduce its thickness to precise specifications, often within micrometers. This cold working hardens the metal, increasing its strength but reducing its ductility. To counteract this, the strip is subjected to annealing—a heat treatment process where it is heated in a controlled atmosphere furnace and then cooled. This relieves internal stresses, restores ductility, and ensures a soft, pliable material ideal for the bending and welding processes it will encounter in battery pack assembly.

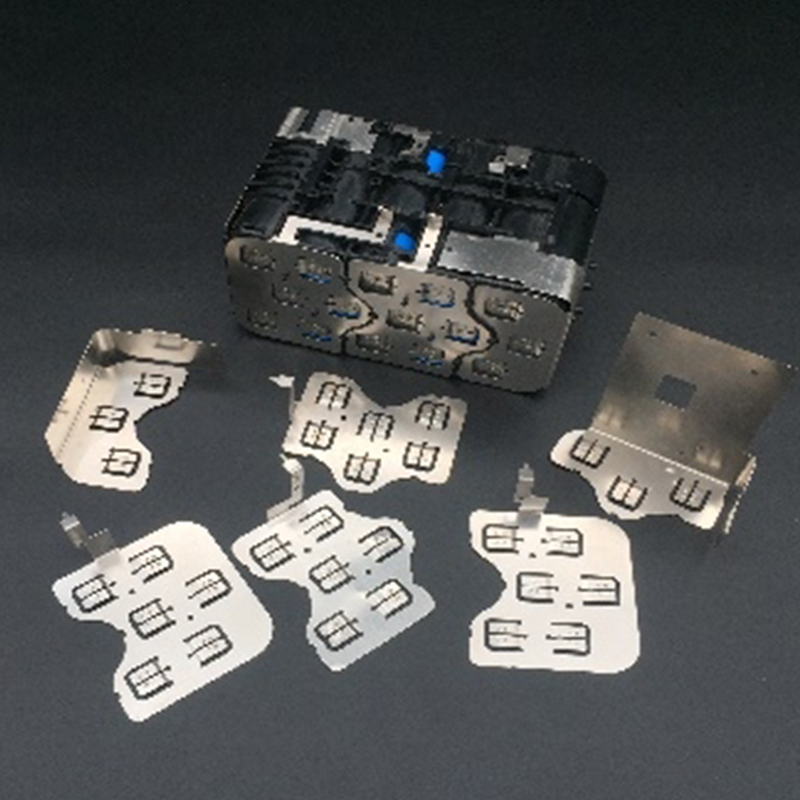

Surface Treatment and Slitting

The final stage prepares the strip for its end-use application. The annealed strip undergoes surface treatments, commonly electroplating or a surface cleaning/passivation process. A thin layer of another metal, like pure nickel or sometimes tin, may be added to improve solderability, enhance electrical contact, and provide resistance to oxidation. Finally, the wide master coil of nickel strip is precisely slit into narrower widths using high-precision slitting machines. This creates the final "belt" or "tape" of the required dimensions, which is then wound onto spools, inspected for defects, and packaged for shipment to battery manufacturers.

Why is Battery Strip Belt Indispensable?

Within the compact ecosystem of a lithium-ion battery pack, every component must perform flawlessly. The nickel strip belt, though seemingly simple, is far from just a piece of metal. Its role is fundamental to the pack's performance, safety, and longevity, making it an indispensable element for three primary reasons.

1. Unmatched Electrical Performance

The core function of the nickel strip is to provide a low-resistance path for electrical current between cells. Nickel is chosen for its electrical conductivity, which is crucial for energy loss as heat during charging and discharging cycles. This efficient current collection and distribution ensure the battery delivers power output and runtime. Without this high-conductivity bridge, the energy stored within the individual cells would be inaccessible, rendering the battery pack ineffective.

2. Essential Structural Integrity

A battery pack is subject to vibration, shock, and thermal expansion. The nickel strip must possess mechanical properties that allow it to withstand these stresses without failing. Its inherent strength and ductility, achieved through precise manufacturing, ensure the physical connections between cells remain secure over the battery's entire lifespan. This structural role prevents disconnections that could power failure and secures the cells firmly in place, maintaining the pack's physical integrity under demanding conditions.

3. Critical Thermal and Safety Management

Battery strips play a subtle but vital role in thermal management. Their consistent quality and secure welding points ensure current flows evenly, preventing localized hot spots that can thermal runaway—a dangerous chain reaction. Furthermore, by enabling an efficient and reliable series connection, they ensure the battery management system (BMS) can accurately monitor and balance the voltage of individual cells. This precise control is paramount for safe operation, preventing overcharging or over-discharging, which are primary causes of battery degradation and safety hazards.

boo@zjmgmm.com / 958587858@qq.com

boo@zjmgmm.com / 958587858@qq.com English

English русский

русский Español

Español عربى

عربى

English

English  Building 33, Demonstration Park, No. 318 Chenguang Road, Eastern New District, Wenling City, Taizhou City, Zhejiang Province, China

Building 33, Demonstration Park, No. 318 Chenguang Road, Eastern New District, Wenling City, Taizhou City, Zhejiang Province, China  0086-576-86337978

0086-576-86337978  0086-576-86333878

0086-576-86333878

boo@zjmgmm.com

boo@zjmgmm.com