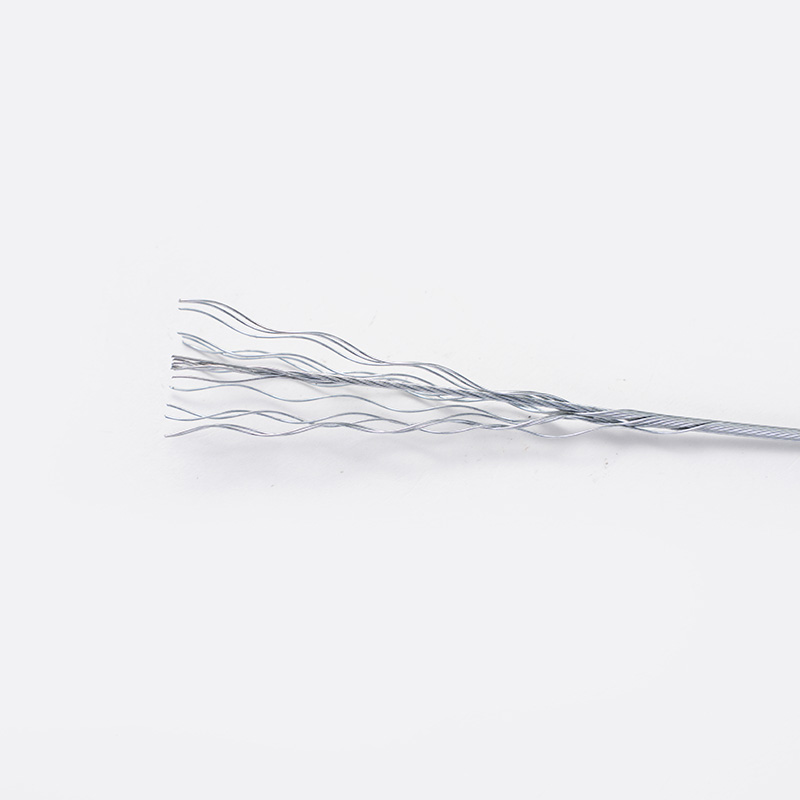

Emergency brake cable parts are critical components in the safety systems of vehicles. The inner wire of the emergency brake cable, in particular, plays a significant role in ensuring the reliable operation of the braking system. This article delves into the processes that the inner wire of emergency brake cable parts undergoes, from its initial stages to becoming a finished component ready for use.

Manufacturing Process Overview

The production of the inner wire for emergency brake cable parts involves several steps, each designed to ensure the wire's durability, strength, and reliability. Here's a detailed look at these processes:

1. Material Selection

The step in the production process is selecting the right material for the inner wire. High-quality steel is typically chosen due to its strength and flexibility. The material must meet specific tensile strength requirements to ensure it can withstand the forces exerted during braking.

2. Drawing

Once the material is selected, it undergoes the drawing process. This involves pulling the steel through a series of dies to reduce its diameter and increase its tensile strength. The drawing process aligns the steel's grain structure, which improves its overall strength and ductility.

3. Heat Treatment

After drawing, the wire is subjected to heat treatment processes such as annealing or tempering. This step helps to relieve internal stresses that may have been introduced during the drawing process and further enhances the wire's strength and flexibility.

4. Coating

To protect the inner wire from corrosion and wear, a coating is applied. This coating can be made of various materials, including plastic, zinc, or a combination of both. The coating process can involve dipping the wire in a bath of molten material or applying a layer through electroplating.

5. Inspection and Testing

Before the inner wire can be used in brake cable assemblies, it must undergo rigorous inspection and testing. This includes visual inspections for defects, as well as mechanical testing to ensure the wire meets the required tensile strength and flexibility standards.

6. Assembly and Integration

Once the inner wire has been manufactured and tested, it is integrated into the emergency brake cable assembly. This involves attaching the wire to the cable housing and ensuring that it operates smoothly when the brake is applied.

7. Quality Control

Throughout the entire manufacturing process, quality control checks are performed to ensure that each batch of inner wire meets the required specifications. This includes random sampling and testing to catch any potential issues early in the process.

8. Packaging and Storage

Finally, the finished inner wire is carefully packaged and stored to protect it from damage and corrosion until it is ready for use in brake cable assemblies.

Importance of Quality Control

The processes outlined above are critical in ensuring that the inner wire of emergency brake cable parts is reliable and safe for use. Any compromise in the quality of the wire could brake failure, which can have catastrophic consequences.

Understanding the processes that the inner wire of emergency brake cable parts goes through is essential for anyone involved in the automotive industry. From material selection to quality control, each step plays a vital role in producing a product that meets the high safety standards required for use in vehicles. By adhering to these processes, manufacturers can help ensure the safety of drivers and passengers on the road.

boo@zjmgmm.com / 958587858@qq.com

boo@zjmgmm.com / 958587858@qq.com English

English русский

русский Español

Español عربى

عربى

English

English  Building 33, Demonstration Park, No. 318 Chenguang Road, Eastern New District, Wenling City, Taizhou City, Zhejiang Province, China

Building 33, Demonstration Park, No. 318 Chenguang Road, Eastern New District, Wenling City, Taizhou City, Zhejiang Province, China  0086-576-86337978

0086-576-86337978  0086-576-86333878

0086-576-86333878

boo@zjmgmm.com

boo@zjmgmm.com