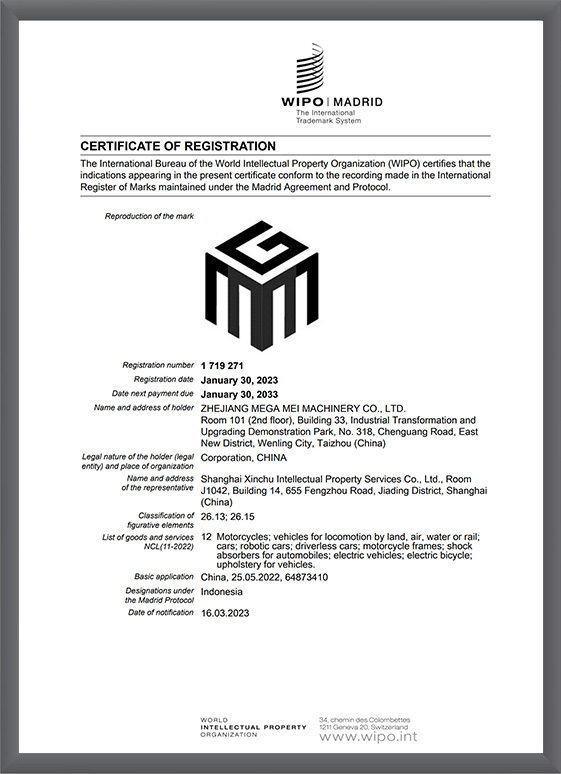

Zhejiang Mega Mei Machinery Co., Ltd. is a China Battery Module Balance Repair Analyzer Manufacturer and Sale Battery Module Balance Repair Analyzer Factory. Relying on the driving effect of the Yangtze River Delta Economic Circle and the unique mechanical processing collective advantage of Wenling, Zhejiang Mega Mei Machinery Co., Ltd. specializes in the production of motorcycle and auto parts such as brake lines and accelerator cables. At present, the products produced by the company are exclusively for Honda and other well-known motorcycle manufacturers at home and abroad. Every link from incoming inspection to packaging and shipping is strictly controlled to ensure that every product from Mega Mei Factory can meet the technical requirements of customers, and can pass the QR code source.

China Lithium Battery Module Analyzer

Battery Module Balance Repair Analyzer

The Battery Module Balance Repair Analyzer with Charging Function is an advanced diagnostic and repair tool designed specifically for lithium-ion battery modules, often used in electric vehicles (EVs) and other energy storage applications. This tool combines both equalization and charging capabilities, making it an essential solution for maintaining and repairing battery modules. As the demand for electric vehicles and renewable energy storage systems continues to rise, the need for efficient battery management solutions becomes even more critical. The Battery Module Balance Repair Analyzer with Charging Function offers a comprehensive and reliable way to ensure optimal battery performance, longevity, and safety.

Application

This analyzer is specifically designed for use in the maintenance, repair, and optimization of lithium-ion battery modules in electric vehicles and other energy storage systems. Its primary application lies in balancing the voltage across the cells in a battery module, ensuring that all cells operate at the same voltage level for optimal performance. The tool also includes a charging function, which allows technicians to charge the battery module as part of the repair or maintenance process.

The Battery Module Balance Repair Analyzer with Charging Function is used by professionals in battery service centers, electric vehicle repair shops, and manufacturers to extend the lifespan of lithium-ion batteries, improve their efficiency, and prevent unnecessary replacements. It can also be used in fleet maintenance for electric vehicles, ensuring the batteries remain in peak condition and avoid costly downtimes.

Advantages

Voltage Imbalance Correction: One of the primary advantages of this tool is its ability to detect and correct voltage imbalances within a battery module. When cells are not balanced, the battery’s overall performance can degrade, resulting in reduced range for EVs and inefficiency in energy storage systems. This analyzer effectively equalizes the voltage levels across all cells, improving battery performance and extending its life.

Charging Functionality: Unlike traditional analyzers, this tool integrates a charging function, allowing users to charge the battery module during the balancing process. This is particularly beneficial when dealing with partially discharged or undercharged modules, as it eliminates the need for separate charging equipment. The ability to charge and balance simultaneously streamlines the repair process, making it more efficient and time-saving for technicians.

Comprehensive Diagnostics: The analyzer provides in-depth diagnostics of the battery module, measuring key parameters such as voltage, temperature, resistance, and overall health of the individual cells. This feature helps technicians assess the condition of the battery, identify faulty cells, and determine whether a repair, replacement, or rebalancing is necessary. The detailed diagnostic reports allow for more informed decision-making and better planning for future maintenance.

Increased Battery Lifespan: By regularly balancing the cells and addressing any imbalances early on, the analyzer helps prevent overcharging or deep discharging, both of which can shorten the lifespan of a battery. Maintaining proper balance within the battery ensures it operates more efficiently and reliably over time, reducing the likelihood of early failures.

User-Friendly Interface: The Battery Module Balance Repair Analyzer with Charging Function features a user-friendly interface, making it easy for technicians to operate and understand. The real-time data display provides clear insights into the battery’s condition, and the simple controls streamline the process of balancing, charging, and diagnosing.

Safety Features: Safety is a key concern when working with high-voltage lithium-ion batteries, and this analyzer incorporates various safety mechanisms to prevent accidents. These include overvoltage protection, thermal management, and short circuit prevention, ensuring that both the user and the battery are protected during the balancing and charging process.

-

Threaded long screw rods are widely used in motor-driven applications, including linear actuators, p...

READ MORE -

In the world of battery technology, particularly in electric vehicles (EVs) and energy storage syste...

READ MORE -

Compared with other lithium-ion chemistries, such as NMC (nickel manganese cobalt) or LCO (lithium c...

READ MORE -

The evolution of eBikes (electric bicycles) has transformed cycling into a more accessible and enjoy...

READ MORE -

What are the key advantages of LiFePO4 chemistry compared to traditional lead-acid batteries for a 1...

READ MORE

How Do We Maintain Battery Health?

In the evolving landscape of energy storage, from electric vehicles to grid support systems, the lithium-ion battery module stands as a fundamental building block. Its performance, longevity, and, most critically, its safety are paramount. However, like any complex system, these modules are susceptible to wear and imbalance over time. Maintaining them requires not just periodic care but sophisticated diagnostic tools. What are the instruments that specialists use to peer into the health of a battery, and how do they differ in their approach to ensuring reliability and function?

What is a Battery Module Balance Repair Analyzer?

A Battery Module Balance Repair Analyzer is an advanced diagnostic and maintenance tool designed specifically for lithium-ion battery modules. Its name describes its dual purpose: analysis and active repair. Fundamentally, it is a device that interfaces with a battery module—a collection of individual cells connected in series and/or parallel—to assess its condition and correct a common ailment known as voltage imbalance.

Unlike a simple voltmeter that might take a single reading, this analyzer connects to the module's individual cell taps, allowing it to measure the voltage of each cell within the module simultaneously. It identifies cells that have strayed from the voltage of their neighbors, a state that diminishes the module's overall capacity and can lead to premature failure. Where it earns the "Repair" part of its name is in its subsequent function: it can gently discharge the higher-voltage cells, bringing them down to the level of the lowest-voltage cell in the chain. This process, called balancing or equalization, effectively resets the module to a state of harmony, restoring its usable capacity and preventing the overcharging or over-discharging of individual cells. It is a crucial tool for refurbishment and lifecycle management.

What is the function of a Lithium Battery Module Analyzer?

While the Balance Repair Analyzer has an active repair function, a Lithium Battery Module Analyzer is a broader term for a device focused primarily on comprehensive testing and evaluation. Its core function is to provide a detailed health report on a battery module. This is achieved through a series of sophisticated tests that go far beyond simple voltage checks.

The primary functions include:

Capacity Testing: This is the most critical test. The analyzer performs a full charge and discharge cycle on the module while precisely measuring the total energy (in Amp-hours, Ah) it can store and deliver. This reveals any degradation in the module's ability to hold a charge.

Internal Resistance (IR) Testing: The device measures the resistance within each cell. A high or increasing internal resistance is a key indicator of cell aging, damage, or internal faults. It leads to energy loss as heat and reduces the module's power output capability.

Voltage and Balance Check: Like the repair analyzer, it checks the voltage of every cell to assess the state of balance within the module.

Data Logging and Reporting: These analyzers record all test parameters over time, generating detailed reports that track performance trends. This data is invaluable for predicting remaining useful life and scheduling proactive maintenance.

What is the difference between a Lithium Battery Pack Equalizer and an Analyzer?

The key difference between a Lithium Battery Pack Equalizer and an Analyzer lies in their purpose and operation: one is a passive maintenance device, and the other is an active diagnostic tool.

A Lithium Battery Pack Equalizer (or Balancer) is a focused device whose sole purpose is to maintain cell voltage balance. It is often a smaller, simpler circuit that can be installed directly onto a battery pack. It continuously monitors cell voltages and, during charging or even at rest, works to redistribute energy from higher-voltage cells to lower-voltage cells (in active balancing systems) or bleed off excess energy from high cells as heat (in passive balancing systems). Its operation is automatic, preventative, and happens in the background, like a continuous drip-feed of medicine to keep the system healthy.

Conversely, a Battery Module Analyzer is a comprehensive, offline diagnostic station. It is not permanently installed but is used periodically by technicians for deep testing. Its role is not continuous maintenance but intermittent, in-depth analysis. It provides a wide array of data—capacity, internal resistance, balance—to form a complete picture of health. While some analyzers can also perform balancing functions, their primary value is in diagnosis and verification.

boo@zjmgmm.com / 958587858@qq.com

boo@zjmgmm.com / 958587858@qq.com English

English русский

русский Español

Español عربى

عربى

English

English  Building 33, Demonstration Park, No. 318 Chenguang Road, Eastern New District, Wenling City, Taizhou City, Zhejiang Province, China

Building 33, Demonstration Park, No. 318 Chenguang Road, Eastern New District, Wenling City, Taizhou City, Zhejiang Province, China  0086-576-86337978

0086-576-86337978  0086-576-86333878

0086-576-86333878

boo@zjmgmm.com

boo@zjmgmm.com