One of the significant advantages of Outer Stranding lies in its ability to create cables that balance resilience and pliability in equal measure. By tailoring the twist, pitch, and angle during Outer Stranding, manufacturers achieve grooves and clearances that let individual strands move slightly under load, distributing stress more evenly. Such a mastery of Outer Stranding prevents premature fatigue and drastically increases the working life of ropes in oil‑rig winches, crane hoists, and elevator systems. I often describe Outer Stranding as the secret ingredient that turns ordinary steel strands into super‑alloys of flexibility.

When it comes to the actual process, the Outer Stranding methodology involves placing pre‑stranded cores through a braiding station where secondary strands are added and carefully tensioned. In the field, technicians must monitor torque, additional wraps, and angular momentum precisely—any deviation can undermine the benefits of Outer Stranding. When performed correctly, Outer Stranding reduces internal friction and enhances the cable’s ability to withstand bending over sheaves and pulleys. Observing this technique in action is like watching a choreographed dance of steel that emerges perfectly symmetrical and ready for duty.

Material selection plays a pivotal role in advanced Outer Stranding systems. High‑performance alloys, stainless steel, and even synthetic fibers can serve as the base strands, while outer layers may incorporate epoxy‑coated or galvanic layers for corrosion resistance. Reinforcements in Outer Stranding, such as polymer matrix composites or aramid fiber wraps, further enhance cut resistance and abrasion longevity. In my laboratory tests, cables made with reinforced Outer Stranding showed up to a 40% improvement in cut life over standard constructions.

What is the Metal Clad Cable for Motorcycle Brakes?

Definition and Function

Motorcycles rely heavily on precise control systems, with the braking system being one of the critical components for rider safety. Among the essential parts of this system is the metal clad cable for motorcycle brakes. A metal clad brake cable is designed to transmit the force from the brake lever to the braking mechanism efficiently. Its outer casing, made of metal and sometimes combined with a protective polymer layer, protects the inner cable from wear, corrosion, and mechanical stress.

When a rider pulls the brake lever, tension is applied to the inner cable, activating the brake caliper or drum. The metal cladding ensures smooth transmission of this force, even under heavy use or in harsh conditions such as rain, mud, or dust. By shielding the inner cable, the metal cladding extends the cable’s lifespan while maintaining consistent braking performance.

Installation and Advantages

Installing a metal clad cable is usually straightforward, and the cable is compatible with a wide range of motorcycles. The rigid outer casing helps maintain cable alignment, reducing flex and improving brake responsiveness. This makes it especially suitable for off-road motorcycles or vehicles frequently exposed to tough environmental conditions.

The metal clad brake cable provides durability, efficiency, and reliability. It ensures riders enjoy consistent braking performance and minimizes the need for frequent replacements, making it a preferred choice for those who value both safety and longevity.

What are the Features of the Universal Motorcycle Brake Cable?

Versatility and Adaptability

The universal motorcycle brake cable is designed to fit a wide variety of motorcycles. Unlike model-specific cables, universal cables allow riders to replace or upgrade their brake systems without being limited by brand or model. This is particularly useful for riders with multiple motorcycles or older bikes with discontinued parts.

Universal brake cables often come in adjustable lengths or can be trimmed to match specific setups. This ensures proper tension and alignment between the brake lever and the caliper or drum, providing smooth and consistent braking.

Durability and Protection

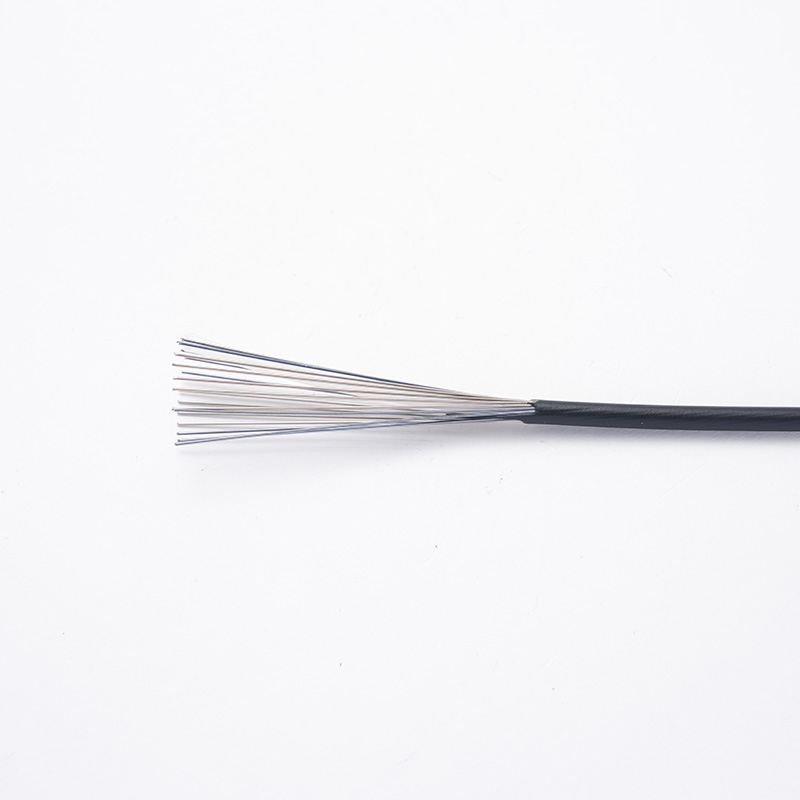

A high-quality universal brake cable features a strong inner core, typically made of steel strands, which resists stretching and ensures reliable force transmission over time. The outer sheath is corrosion-resistant and flexible, protecting the inner cable from dust, moisture, and abrasion. Some cables also include low-friction liners or lubrication to further enhance responsiveness and reduce wear.

Compatibility and Ease of Use

Many universal brake cables are compatible with both front and rear brakes. Pre-installed end fittings often make installation simple and convenient. Riders benefit from consistent lever feel, minimal drag, and precise braking performance, enhancing both safety and comfort.

In summary, the universal motorcycle brake cable offers adaptability, durability, and efficient operation. Its versatile design makes it an essential component for riders seeking reliable braking solutions across multiple motorcycle models.

Key Differences

While both metal clad and universal brake cables aim to improve braking performance, they serve slightly different purposes. Metal clad cables focus on durability and protection in harsh conditions, making them ideal for off-road or heavy-use motorcycles. Their rigid outer casing ensures consistent performance and minimizes wear.

Universal brake cables, on the other hand, prioritize versatility and adaptability. They are suitable for a wide range of motorcycle models and can be easily adjusted or trimmed for a proper fit. While they also offer durability, their main advantage is flexibility, allowing riders to maintain or upgrade braking systems without worrying about model compatibility.

Practical Implications

For riders who frequently encounter rough terrain or adverse weather conditions, a metal clad cable may provide longevity and reliability. Meanwhile, universal cables are well-suited for riders who own multiple motorcycles, need easy replacements, or prefer adjustable solutions for both front and rear brakes.

Final Thoughts

Both types of brake cables play important roles in motorcycle safety. Choosing between them depends on individual riding conditions and preferences. Understanding the features and benefits of each option can help riders make informed decisions, ensuring braking performance and enhanced safety on the road.

boo@zjmgmm.com / 958587858@qq.com

boo@zjmgmm.com / 958587858@qq.com English

English русский

русский Español

Español عربى

عربى

English

English  Building 33, Demonstration Park, No. 318 Chenguang Road, Eastern New District, Wenling City, Taizhou City, Zhejiang Province, China

Building 33, Demonstration Park, No. 318 Chenguang Road, Eastern New District, Wenling City, Taizhou City, Zhejiang Province, China  0086-576-86337978

0086-576-86337978  0086-576-86333878

0086-576-86333878

boo@zjmgmm.com

boo@zjmgmm.com