The braking system in a vehicle is its critical safety feature. Every component within this system must function flawlessly to ensure the driver maintains complete control. Among these parts, the brake cable—a key element in parking brake systems and some older primary brake systems—is often overlooked until a significant problem arises. Procrastinating on its replacement is a dangerous gamble. The reasons for prompt action are multifaceted, encompassing immediate safety risks, the potential for cascading damage, and the overarching value of preventative maintenance.

The Imminent Safety Hazard

The compelling reason for immediate replacement is the direct threat to vehicle safety. A malfunctioning brake cable can fail without warning, a complete loss of braking power in the systems it controls. For a parking brake, this means the vehicle may not remain stationary on an incline, potentially a runaway car that can cause property damage or personal injury. In systems where the cable actuates the primary brakes, a failure is catastrophic, resulting in an inability to slow or stop the vehicle. Even a partially compromised cable introduces a dangerous variable. It can cause the brakes to engage unevenly, vehicle pulling during braking, which drastically increases the risk of losing control, especially in emergency maneuvers or adverse weather conditions.

Preventing Costly Secondary Damage

Ignoring a faulty brake cable contains the problem to a single component. A stretched or damaged cable often forces the driver to apply excessive force to the brake lever or pedal to achieve the desired stopping effect. This excess strain does not vanish; it is transferred through the braking system. This can premature wear and potential damage to other components, such as the brake calipers, levers, shoes, or drums. What begins as a simple, relatively inexpensive cable replacement can quickly escalate into a much larger and more costly repair bill. Replacing the $50 cable promptly can prevent the need to replace a $300 caliper later, making it a financially prudent decision in the long run.

The Principle of Preventative Maintenance

A vehicle is a complex machine where systems are interdependent. Adhering to a schedule of preventative maintenance is the practice for ensuring longevity, reliability, and safety. Addressing a worn brake cable promptly is a prime example of this philosophy. It demonstrates a proactive approach to vehicle care, identifying and resolving a minor issue before it matures into a major failure. This vigilance provides immense peace of mind. Knowing that every critical system, especially the brakes, is in condition allows for confident and secure driving. It eliminates the nagging worry of a potential failure and reinforces the driver's responsibility for their safety and the safety of others on the road.

What are the steps for replacing brake lines and accelerator cables?

Replacing brake lines and accelerator cables requires mechanical knowledge and a methodical approach. For brake lines, begin by safely lifting the vehicle and securing it on jack stands. Identify the damaged section of metal tubing or flexible hose. Using a flare-nut wrench, carefully disconnect the line at both fitting ends to avoid rounding the nuts. Prepare a new pre-flared line of the same length and diameter, bending it to match the old line’s route to avoid kinks. Install the new line, hand-tightening the fittings before finalizing with the wrench. The system must then be bled to remove air, a process requiring a partner to pump the brake pedal while you open and close bleed valves at each wheel. For accelerator cables, the process is simpler. Inside the car, disconnect the cable end from the throttle pedal. Under the hood, detach it from the throttle linkage and any guide clips. Carefully route the new cable along the identical path, securing it in all clips, and connect it at the throttle body and pedal. Finally, verify the throttle operates smoothly without binding before starting the engine.

What are the signs of a malfunctioning auto brake cable?

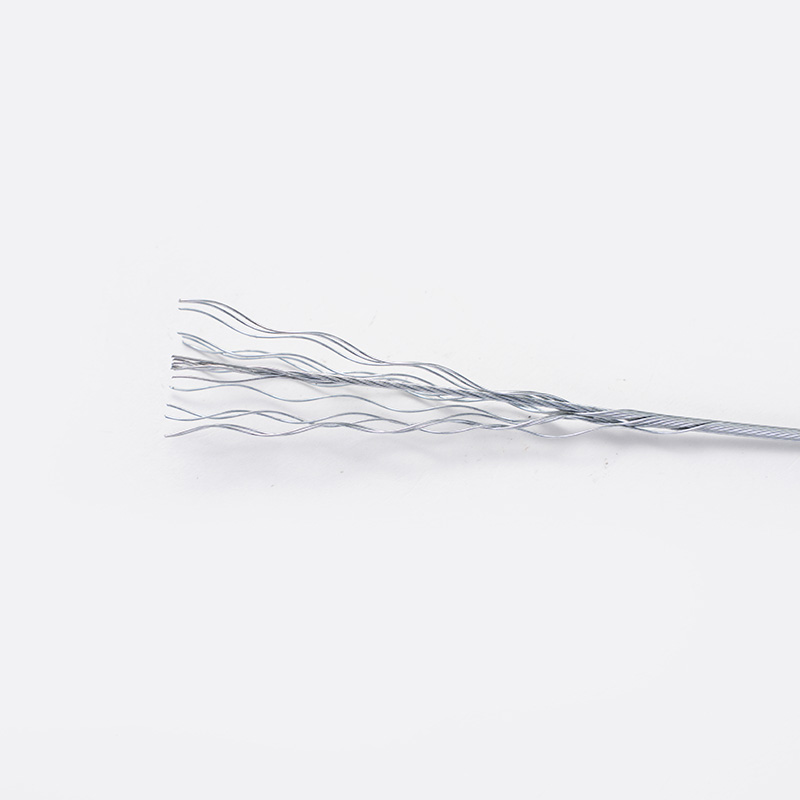

Several clear indicators point to a failing brake cable, commonly in a parking brake system. The frequent sign is a loose feeling or excessive travel in the parking brake lever or pedal when engaged. You may find you have to pull the lever much higher than usual to achieve any resistance, indicating the cable has stretched. Conversely, a brake cable that is seized or corroded may not release fully, manifesting as a dragging brake. This is often accompanied by a burning smell from overheated brakes, reduced fuel efficiency, and even visible smoke from a wheel. Another sign is the complete failure of the parking brake to hold the vehicle on an incline. If the lever pulls up but the car still rolls, the cable may be broken internally. Finally, a visual inspection can reveal problems; look for severe rust, fraying wires at the cable ends, or a damaged protective housing that could allow corrosion to set in.

boo@zjmgmm.com / 958587858@qq.com

boo@zjmgmm.com / 958587858@qq.com English

English русский

русский Español

Español عربى

عربى

English

English  Building 33, Demonstration Park, No. 318 Chenguang Road, Eastern New District, Wenling City, Taizhou City, Zhejiang Province, China

Building 33, Demonstration Park, No. 318 Chenguang Road, Eastern New District, Wenling City, Taizhou City, Zhejiang Province, China  0086-576-86337978

0086-576-86337978  0086-576-86333878

0086-576-86333878

boo@zjmgmm.com

boo@zjmgmm.com