What are the Sizes of Automobile/Motorcycle Steel Wire Inner Wire?

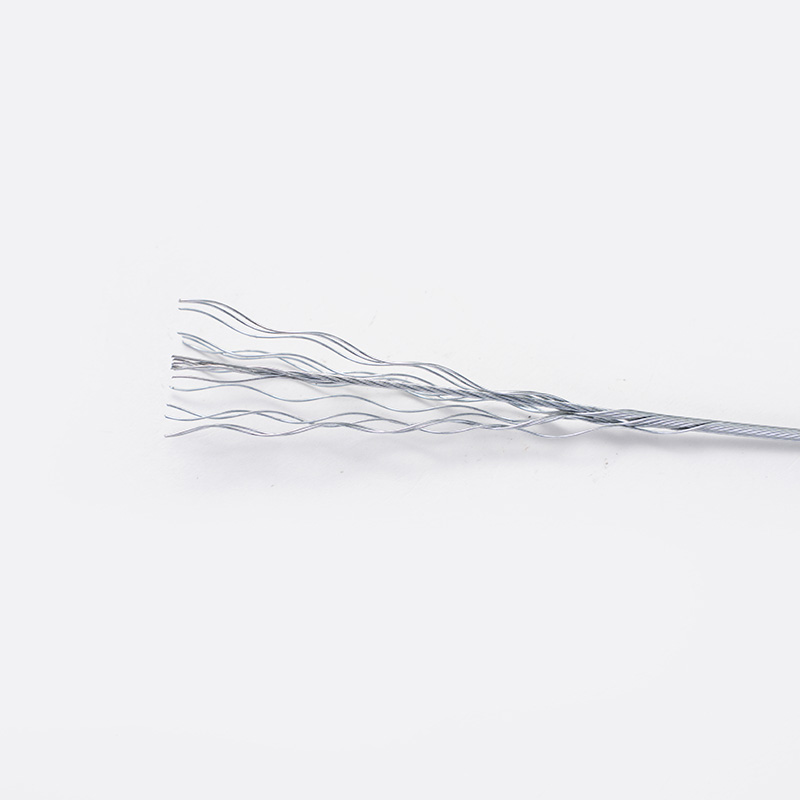

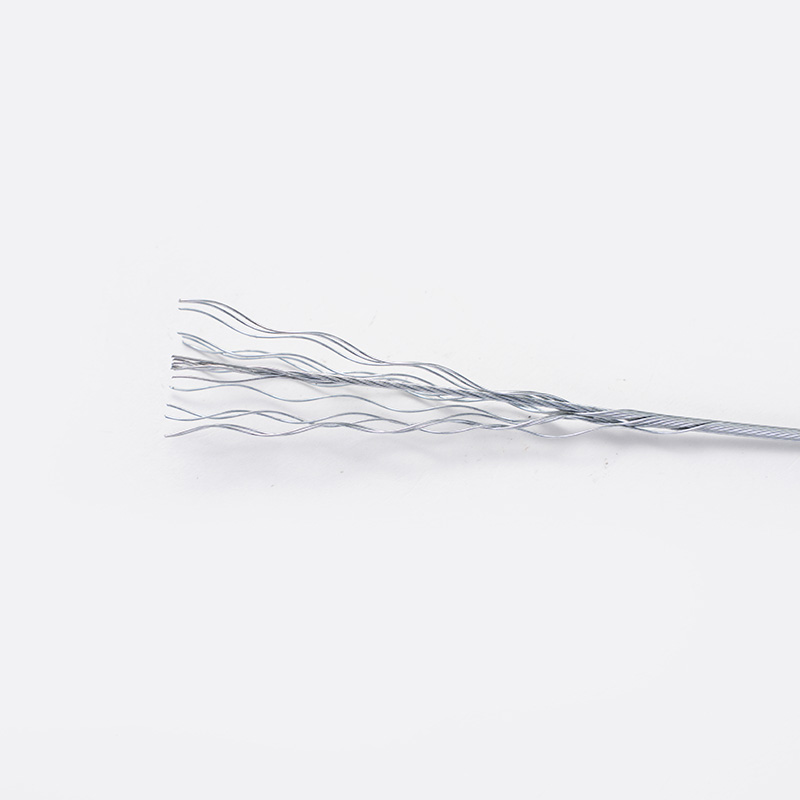

Steel wire inner wires, also known as core wires, are the backbone of many cable systems in automobiles and motorcycles. These wires come in various sizes to cater to the different requirements of each vehicle. The size of a steel wire inner wire is typically measured by its diameter, which can range from a few millimeters to several centimeters. The selection of wire size depends on the specific application, load capacity, and the space available within the vehicle.

In automotive and motorcycle applications, the common sizes for steel wire inner wires are in the range of 0.5mm to 2.5mm in diameter. Thinner wires are used for lighter duties, such as electrical connections and small control mechanisms, while thicker wires are employed for heavy-duty applications like brake and clutch systems. The choice of wire size is also influenced by the need for flexibility, as thinner wires are more pliable and can be routed through tight spaces within the vehicle's frame.

It's important to note that the size of the steel wire inner wire is not the only factor to consider; the number of strands or the construction of the wire also plays a significant role in its strength and performance. Multiple strands twisted together can increase the wire's tensile strength and durability, making it suitable for high-stress applications.

What are the Characteristics of the Material of Clutch/Brake Inner Wire?

The material of clutch and brake inner wires must possess certain characteristics to ensure reliable performance and longevity. These characteristics include high tensile strength, resistance to corrosion, and the ability to withstand high temperatures and stress.

Tensile strength is crucial for these wires, as they are subjected to significant forces during braking and clutch operations. Steel is the common material used due to its high strength-to-weight ratio and affordability. However, not all steels are created equal; high-carbon steel and stainless steel are preferred for their strength and corrosion resistance, respectively.

Corrosion resistance is another important characteristic, especially for wires that are exposed to the elements or are in constant contact with fluids. Galvanization or the use of stainless steel can provide a protective layer against rust and other forms of corrosion, prolonging the life of the wire.

Temperature resistance is also a key factor, as brake and clutch systems can generate high heat during operation. The material of the inner wire must be able to maintain its integrity and not lose strength at elevated temperatures.

The material should also have good fatigue resistance, as the wires are subjected to repeated stress and strain over time. This ensures that the wire does not fail prematurely due to cyclic loading.

How Did Brake Inner Cables Come About?

The development of brake inner cables is closely tied to the evolution of braking systems in automobiles and motorcycles. Early braking systems relied on mechanical linkages, which were gradually replaced by hydraulic systems for their efficiency and ease of use.

With the advent of hydraulic brakes, the need for a reliable and durable way to transmit the force applied at the brake lever to the calipers became apparent. This led to the development of brake inner cables, which serve as the link between the lever and the calipers. The cables are designed to withstand the high pressures generated during braking and to provide a smooth and responsive feel to the rider or driver.

The materials and construction of these cables have evolved to meet the increasing demands of performance and safety. Early cables were made from simple steel wires, but as the understanding of materials science improved, so did the cables. The introduction of stranded steel wires, coated cables, and even Teflon-lined cables has allowed for better performance, reduced friction, and improved resistance to the elements.

boo@zjmgmm.com / 958587858@qq.com

boo@zjmgmm.com / 958587858@qq.com English

English русский

русский Español

Español عربى

عربى

English

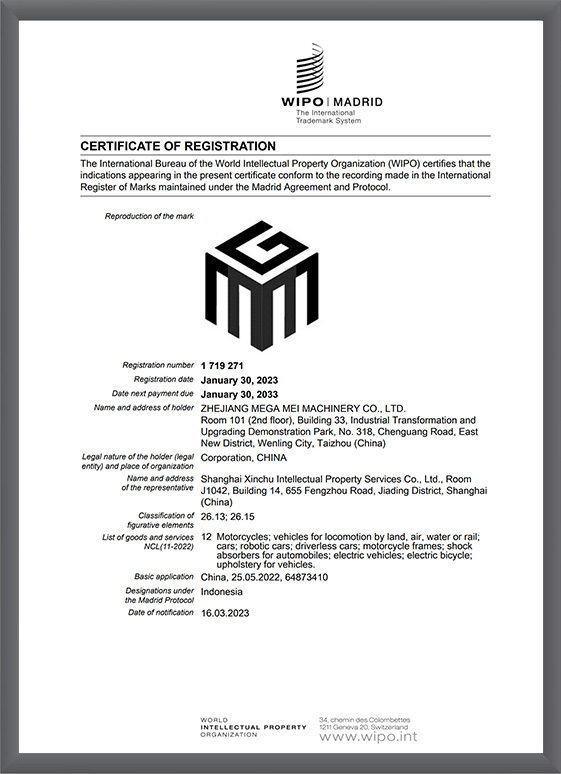

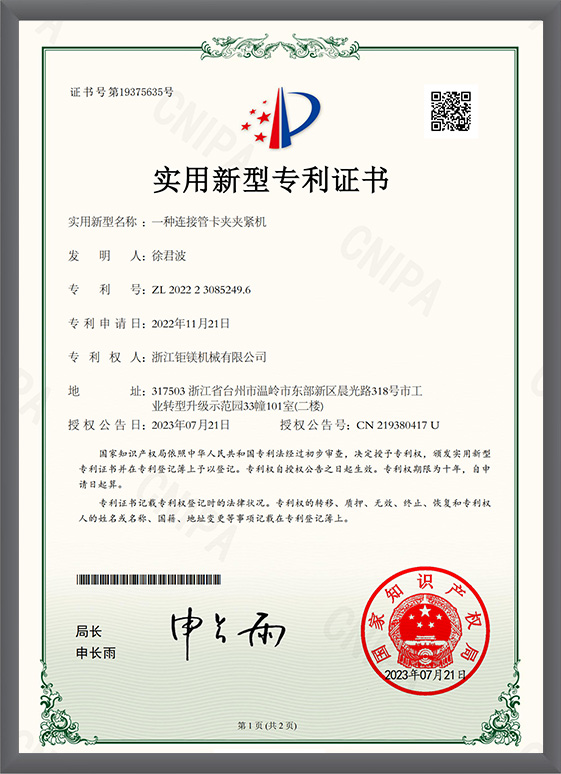

English  Building 33, Demonstration Park, No. 318 Chenguang Road, Eastern New District, Wenling City, Taizhou City, Zhejiang Province, China

Building 33, Demonstration Park, No. 318 Chenguang Road, Eastern New District, Wenling City, Taizhou City, Zhejiang Province, China  0086-576-86337978

0086-576-86337978  0086-576-86333878

0086-576-86333878

boo@zjmgmm.com

boo@zjmgmm.com