Industry Knowledge Extension

What Are the Characteristics and Limitations of the Integrated Series Battery?

Integrated series batteries have gained increasing attention in recent years, particularly in the fields of electric vehicles and energy storage systems. These batteries integrate multiple cells in a series connection to achieve higher voltage and more stable power output. Understanding their characteristics, limitations, and applications is crucial for selecting the right battery solution in various industries.

Characteristics:

Integrated series batteries are typically designed for high-power applications. They offer a compact structure, high energy density, and consistent voltage output across all cells. The series connection ensures that the battery can supply sufficient voltage for devices requiring higher power, such as electric vehicles or industrial equipment. Additionally, integrated monitoring systems are often included, allowing for real-time management of individual cell performance and protection against overcharging or deep discharge.

Limitations:

Despite their advantages, Type 1 batteries have notable limitations. One key issue is the dependency of overall performance on the weakest cell in the series. If a single cell fails, it can reduce the efficiency or even damage the entire battery pack. Thermal management is another challenge, as series-connected cells can generate heat unevenly, which may accelerate degradation if not controlled. Moreover, the higher manufacturing cost and complexity of assembling integrated series batteries can be a barrier for large-scale adoption.

Characteristics:

Integrated series batteries focus on safety and longevity. They often use lithium iron phosphate (LiFePO4) chemistry, which provides enhanced thermal stability and longer cycle life. These batteries are less prone to overheating and are well-suited for applications requiring reliable, long-term energy storage. Their modular design allows easier replacement or maintenance of individual cells without affecting the whole system.

Limitations:

However, Type 2 batteries generally have lower energy density compared to other lithium-ion chemistries, which limits their suitability for applications where weight and space are critical. The initial investment can also be higher due to the use of specialized materials and safety features. Additionally, the lower voltage output of LiFePO4-based integrated series batteries may require additional design adjustments in high-voltage systems.

What Are the Applications of the Lithium Iron Phosphate Integrated Battery?

Lithium iron phosphate integrated batteries have become increasingly popular due to their safety, stability, and long cycle life. They are widely applied in three main areas:

1. Electric Vehicles:

Lithium iron phosphate integrated batteries are commonly used in electric buses, cars, and trucks. Their stable discharge characteristics and thermal safety make them particularly suitable for vehicles that operate over long distances or in high-temperature environments. The long lifespan of LiFePO4 batteries also reduces maintenance costs, making them cost-effective for commercial fleets.

2. Energy Storage Systems:

These batteries are often implemented in residential, commercial, and industrial energy storage systems. They can store excess energy from renewable sources such as solar panels or wind turbines and release it when needed. Their high cycle life ensures consistent performance over years, making them ideal for grid stabilization and backup power applications.

3. Portable and Stationary Devices:

Lithium iron phosphate integrated batteries are also used in portable electronics, medical equipment, and stationary devices like uninterruptible power supplies (UPS). Their safety features and steady voltage output provide reliable energy for sensitive devices, while their modular structure allows easy maintenance and replacement.

How Many Types of Lithium Iron Phosphate Batteries Are There?

Lithium iron phosphate (LiFePO4) batteries are a subset of lithium-ion batteries with several variations depending on design, application, and integration method. Broadly, there are three main types:

1. Prismatic LiFePO4 Batteries:

Prismatic batteries use rectangular casings, which allow for efficient space utilization. They are widely used in electric vehicles and energy storage systems because they provide a balance between energy density and thermal management. Their shape allows for modular assembly, making maintenance and replacement easier.

2. Cylindrical LiFePO4 Batteries:

Cylindrical LiFePO4 batteries are designed with a round cell structure. They are easier to manufacture and often have better heat dissipation due to the cylindrical shape. These batteries are suitable for applications requiring consistent power output and durability, such as electric bikes, power tools, and smaller energy storage setups.

3. Integrated or Packaged LiFePO4 Batteries:

Integrated LiFePO4 batteries combine multiple cells into a series or parallel configuration to provide higher voltage and capacity. They often include a battery management system (BMS) for monitoring and protection. These batteries are preferred in large-scale energy storage and commercial electric vehicles because of their safety, modularity, and ability to deliver high power efficiently.

Each type of LiFePO4 battery has its own trade-offs in terms of energy density, cost, thermal performance, and ease of maintenance, allowing engineers to select the suitable option based on specific requirements.

boo@zjmgmm.com / 958587858@qq.com

boo@zjmgmm.com / 958587858@qq.com English

English русский

русский Español

Español عربى

عربى

English

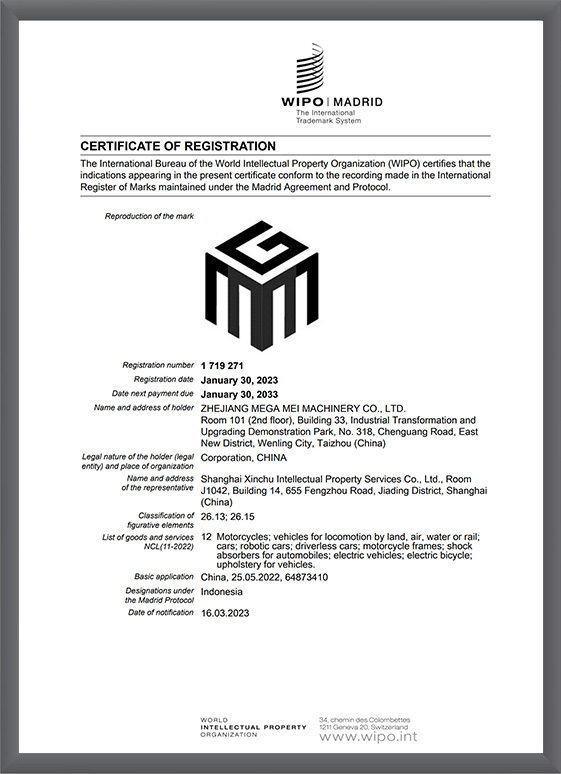

English  Building 33, Demonstration Park, No. 318 Chenguang Road, Eastern New District, Wenling City, Taizhou City, Zhejiang Province, China

Building 33, Demonstration Park, No. 318 Chenguang Road, Eastern New District, Wenling City, Taizhou City, Zhejiang Province, China  0086-576-86337978

0086-576-86337978  0086-576-86333878

0086-576-86333878

boo@zjmgmm.com

boo@zjmgmm.com