Zhejiang Mega Mei Machinery Co., Ltd. is a China Energy Storage Batteries Manufacturer and Sale Energy Storage Batteries Factory. Relying on the driving effect of the Yangtze River Delta Economic Circle and the unique mechanical processing collective advantage of Wenling, Zhejiang Mega Mei Machinery Co., Ltd. specializes in the production of motorcycle and auto parts such as brake lines and accelerator cables. At present, the products produced by the company are exclusively for Honda and other well-known motorcycle manufacturers at home and abroad. Every link from incoming inspection to packaging and shipping is strictly controlled to ensure that every product from Mega Mei Factory can meet the technical requirements of customers, and can pass the QR code source.

Inches Rack Standard Backup Battery Sales

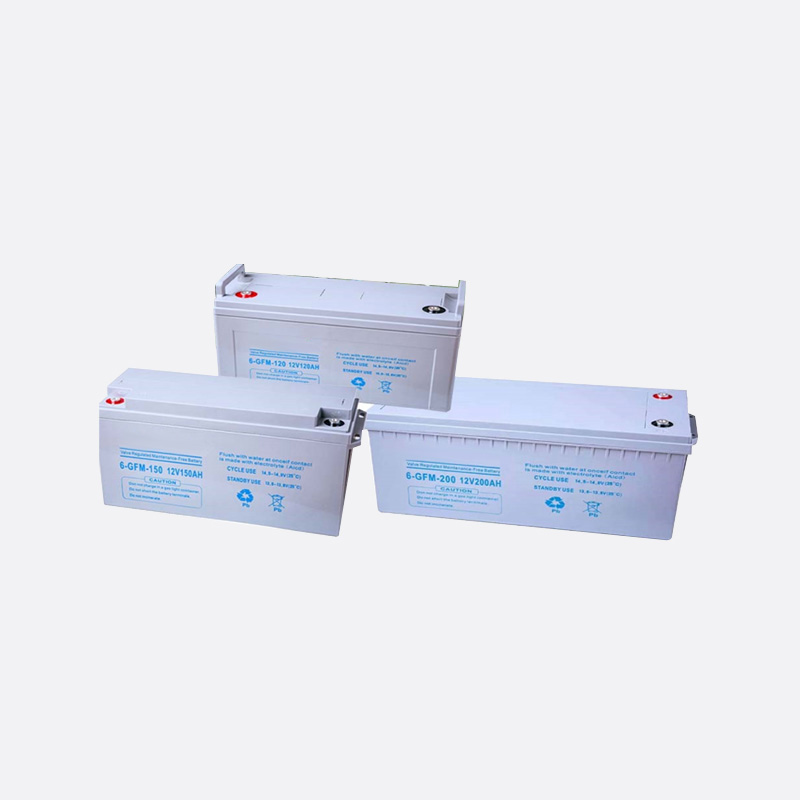

Energy Storage Batteries

Energy Storage Batteries are advanced power storage systems designed to efficiently capture, store, and discharge energy. Built with reliable lithium-ion or other suitable battery technologies, these batteries provide consistent performance across a range of energy environments. We manufacture and supply energy storage solutions that support residential, commercial, and industrial applications, contributing to energy efficiency and operational reliability.

Product Advantages

Reliable Performance

Maintains stable energy output across a range of environmental conditions.Designed to handle repeated charge and discharge cycles with minimal degradation.Equipped with advanced battery management systems to monitor and balance performance.

Long Cycle Life

Offers a high number of charge-discharge cycles, extending product usability.Reduced maintenance requirements contribute to lower operating costs over time.

Scalable Design

Modular configuration supports scaling based on energy demand.Easily integrates with various renewable energy sources or grid systems.

Energy Efficiency

Minimizes energy loss during storage and discharge.Supports load shifting and peak shaving to enhance energy utilization.

Environmental Adaptability

Functions effectively in diverse climatic conditions.Features protective mechanisms for temperature, voltage, and current variations.

Product Features

Intelligent Battery Management System (BMS)Real-time monitoring of voltage, current, and temperature.Balancing of cells to ensure uniform performance and safety.Overcharge, over-discharge, and short circuit protection.

Modular Construction

Units can be added or removed according to capacity requirements. Streamlined maintenance and easy replacement of individual modules.Compact footprint ideal for space-constrained installations.

High Energy Density

Maximizes storage capacity relative to physical size.Reduces space and structural requirements for installation.

-

Threaded long screw rods are widely used in motor-driven applications, including linear actuators, p...

READ MORE -

In the world of battery technology, particularly in electric vehicles (EVs) and energy storage syste...

READ MORE -

Compared with other lithium-ion chemistries, such as NMC (nickel manganese cobalt) or LCO (lithium c...

READ MORE -

The evolution of eBikes (electric bicycles) has transformed cycling into a more accessible and enjoy...

READ MORE -

What are the key advantages of LiFePO4 chemistry compared to traditional lead-acid batteries for a 1...

READ MORE

How do 12V LiFePO4 lithium batteries work?

12V LiFePO4 batteries are widely used as a reliable power source in applications ranging from small electronics to backup power systems. Their working principle combines electrochemistry with stable material properties to provide efficiency and durability.

Electrochemical principle: energy conversion

A 12V LiFePO4 battery consists of several cells connected in series. Each cell has a nominal voltage of about 3.2V, so four cells in series reach approximately 12.8V. The positive electrode is made from lithium iron phosphate, while the negative electrode is usually graphite. During discharge, lithium ions move from the anode to the cathode through an electrolyte, releasing electrons that power connected devices. During charging, the process reverses, and the ions are restored to the anode.

Material advantages: stability and safety

Compared to other lithium-ion chemistries, LiFePO4 offers higher thermal and chemical stability. This reduces risks of overheating and ensures a longer lifecycle. These batteries can typically endure more than 2,000 charge cycles without significant performance loss. Their ability to maintain consistent voltage during discharge also makes them suitable for sensitive equipment that requires a stable energy supply. Overall, the chemistry balances energy density with durability, providing reliable 12V storage without the volatility of alternatives such as lithium cobalt oxide.

What are the inch rack standard backup batteries?

Rack-mounted backup batteries follow industry standards that align with server rack dimensions. These units are essential in data centers, telecommunications facilities, and industrial environments where uninterrupted power is critical.

Rack sizing: integration with server systems

Standard server racks are measured in "U," where 1U equals 1.75 inches in height. Backup batteries are designed to fit within this modular structure, making installation straightforward. Common configurations include 1U, 2U, and 3U battery modules, which can be combined depending on the capacity and redundancy required. By following these standardized dimensions, the batteries can be seamlessly integrated with uninterruptible power supply (UPS) systems in existing rack enclosures.

Application value: reliability in critical operations

Rack-mounted batteries provide immediate backup when grid power fails, ensuring servers, networking devices, or industrial controllers remain online. Their modular design allows users to scale capacity according to operational needs. For instance, a small office might use a single 1U battery pack, while a data center may stack multiple larger units to handle extended power outages. Moreover, their compact form factor allows for better airflow and space efficiency within the rack, balancing performance with practical installation.

What are the characteristics of a stacked series battery?

Stacked series batteries are designed by connecting multiple battery cells or modules in sequence. This configuration increases the total voltage while keeping the current of individual cells consistent. Their characteristics can be summarized in the following table:

|

Characteristic |

Description |

|

Voltage increase |

Connecting cells in series multiplies the voltage, e.g., four 3.2V cells = 12.8V. |

|

Energy density balance |

Provides higher output voltage without necessarily increasing cell size. |

|

Scalability |

Easy to expand for larger systems by adding more modules. |

|

Efficiency |

Maintains stable performance in systems that require consistent higher voltage. |

|

Safety consideration |

Requires careful battery management systems to balance charge and prevent faults. |

|

Common applications |

Electric vehicles, renewable energy storage, and industrial equipment. |

Performance improvement: higher voltage availability

Stacked series batteries are favored in environments where higher voltage is necessary to drive motors, support inverters, or manage large-scale power systems. By combining cells in series, the total voltage output can match the requirements of heavy-duty applications.

System management: role of BMS

To ensure safety and longevity, a battery management system (BMS) monitors each cell’s condition. The BMS balances charging, prevents over-discharge, and avoids overheating. Without such monitoring, uneven charging between cells could lead to efficiency loss or safety risks. This makes the BMS a vital component in stacked battery systems used across renewable energy storage, electric mobility, and industrial operations.

boo@zjmgmm.com / 958587858@qq.com

boo@zjmgmm.com / 958587858@qq.com English

English русский

русский Español

Español عربى

عربى

English

English  Building 33, Demonstration Park, No. 318 Chenguang Road, Eastern New District, Wenling City, Taizhou City, Zhejiang Province, China

Building 33, Demonstration Park, No. 318 Chenguang Road, Eastern New District, Wenling City, Taizhou City, Zhejiang Province, China  0086-576-86337978

0086-576-86337978  0086-576-86333878

0086-576-86333878

boo@zjmgmm.com

boo@zjmgmm.com