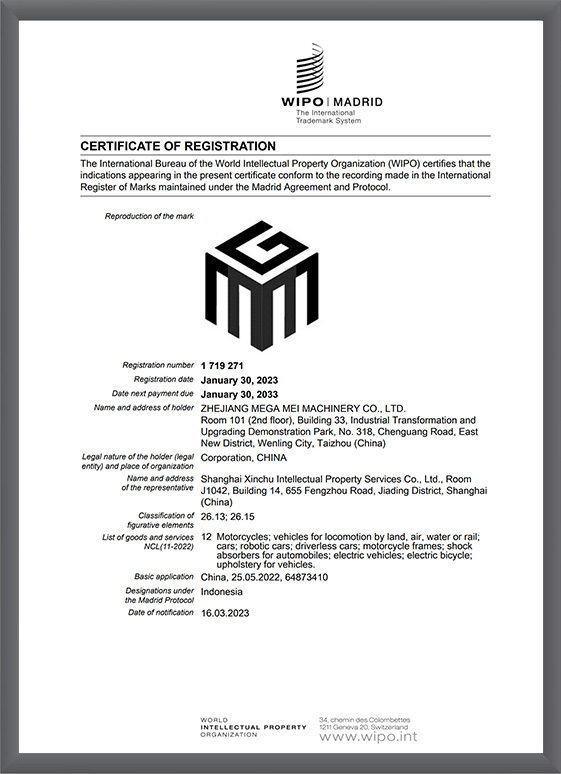

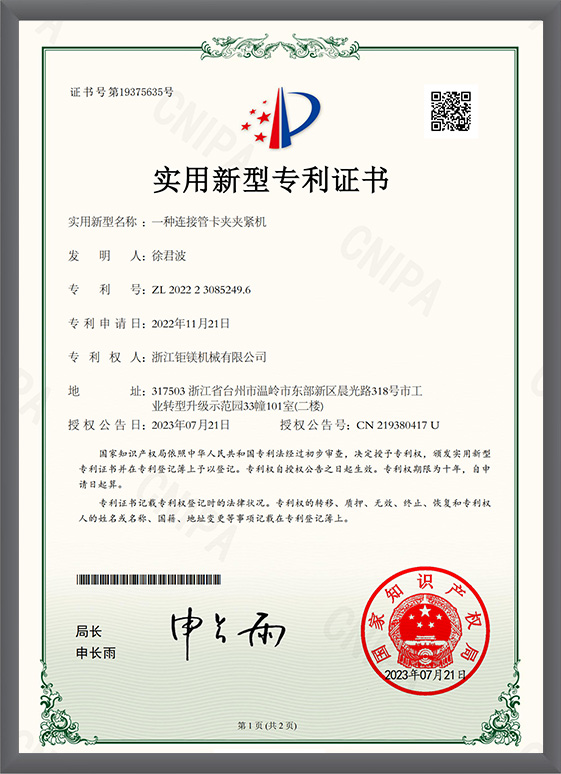

Zhejiang Mega Mei Machinery Co., Ltd. is a China Electric Motorcycle Battery Box Parts (National Standard) Manufacturer and Sale Electric Motorcycle Battery Box Parts (National Standard) Factory. Relying on the driving effect of the Yangtze River Delta Economic Circle and the unique mechanical processing collective advantage of Wenling, Zhejiang Mega Mei Machinery Co., Ltd. specializes in the production of motorcycle and auto parts such as brake lines and accelerator cables. At present, the products produced by the company are exclusively for Honda and other well-known motorcycle manufacturers at home and abroad. Every link from incoming inspection to packaging and shipping is strictly controlled to ensure that every product from Mega Mei Factory can meet the technical requirements of customers, and can pass the QR code source.

-

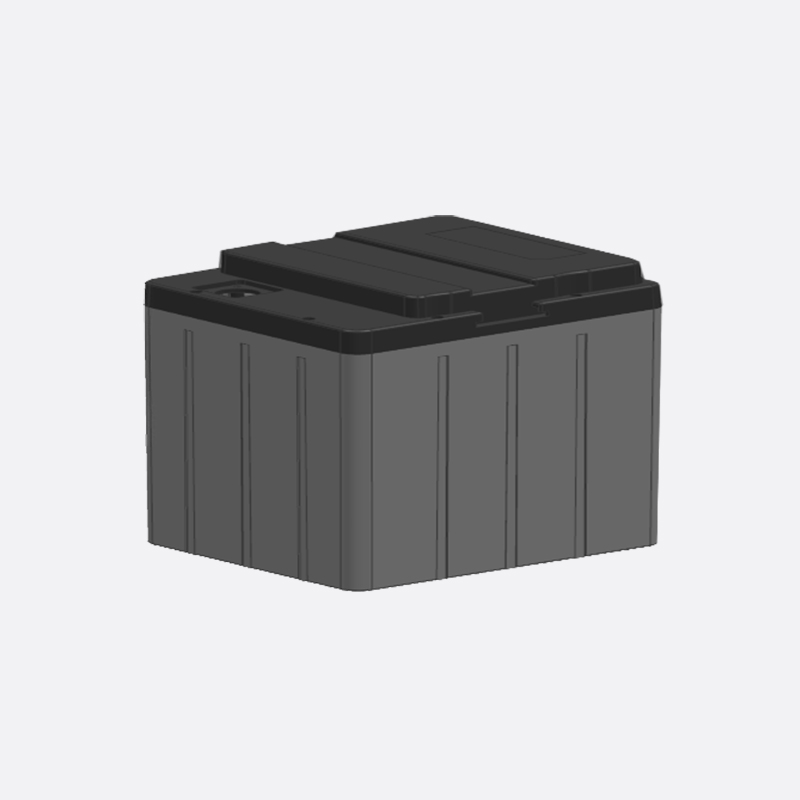

Battery Pack Enclosure mgmm-007

High-Strength Cell Types 18650 mgmm-007 E-Motorcycle Battery Housing For E-Bike

-

Battery Pack Enclosure mgmm-008

Flame-Retardant (FR) Battery Case mgmm-008 E-Motorcycle Battery Housing For E-Bike

-

Battery Pack Enclosure mgmm-4828

Adjustable Cell Types 18650/21700 mgmm-4828 E-Motorcycle Battery Housing For E-Bike

-

Battery Pack Enclosure mgmm-19/20

Battery Shell mgmm -18650/21700/26700 E-Motorcycle Battery Housing For E-Bike

-

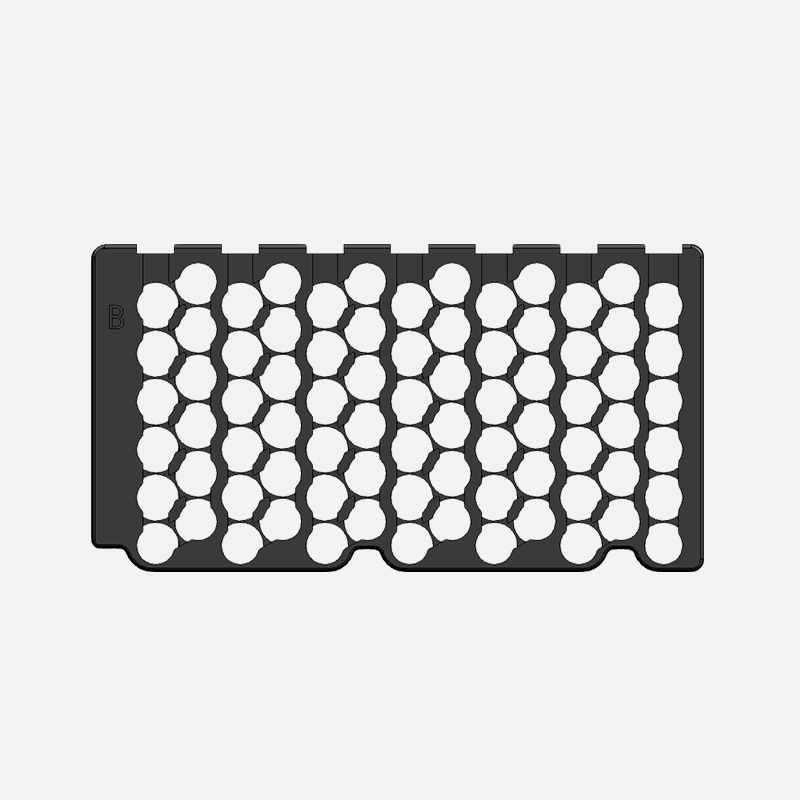

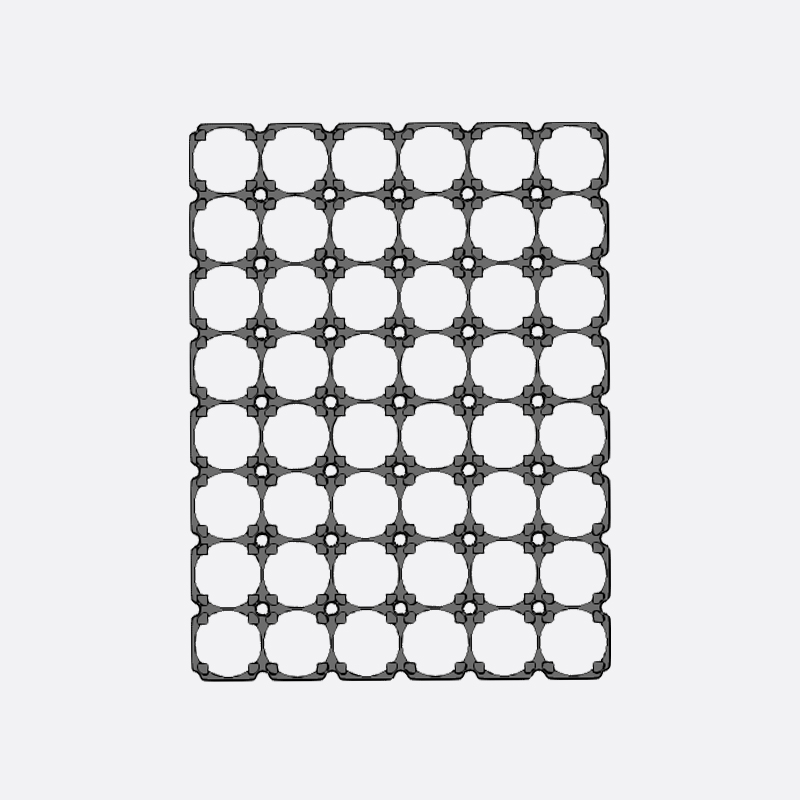

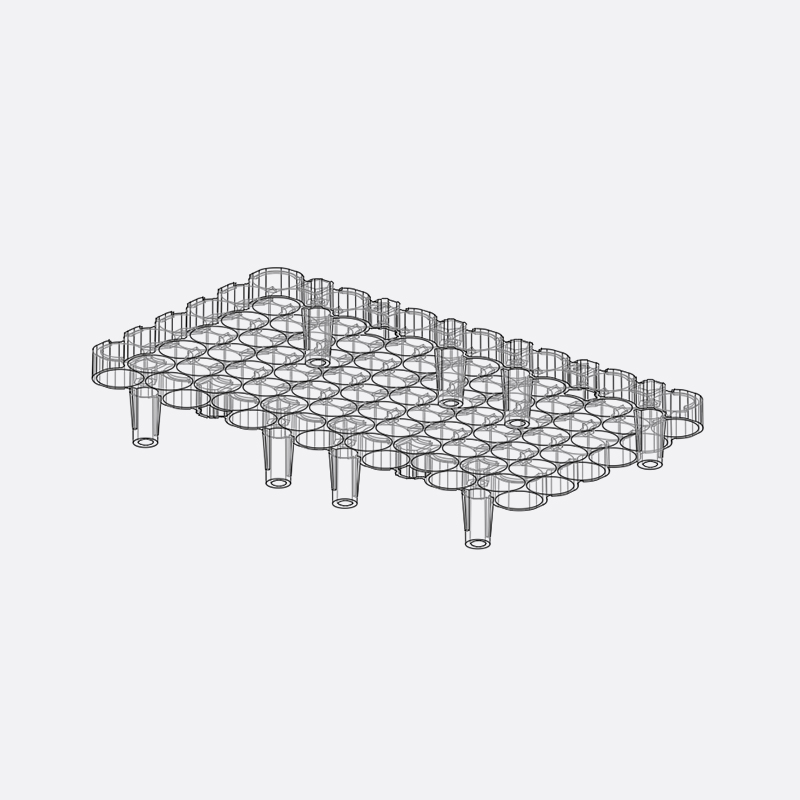

Battery box bracket for electric bicycles mgmm- 4812

Plastic Enclosure (ABS/PC/PP) ABS+PC 007-1 Mesh Bracket Battery Box Abrasion-Resistant For E-Bike

-

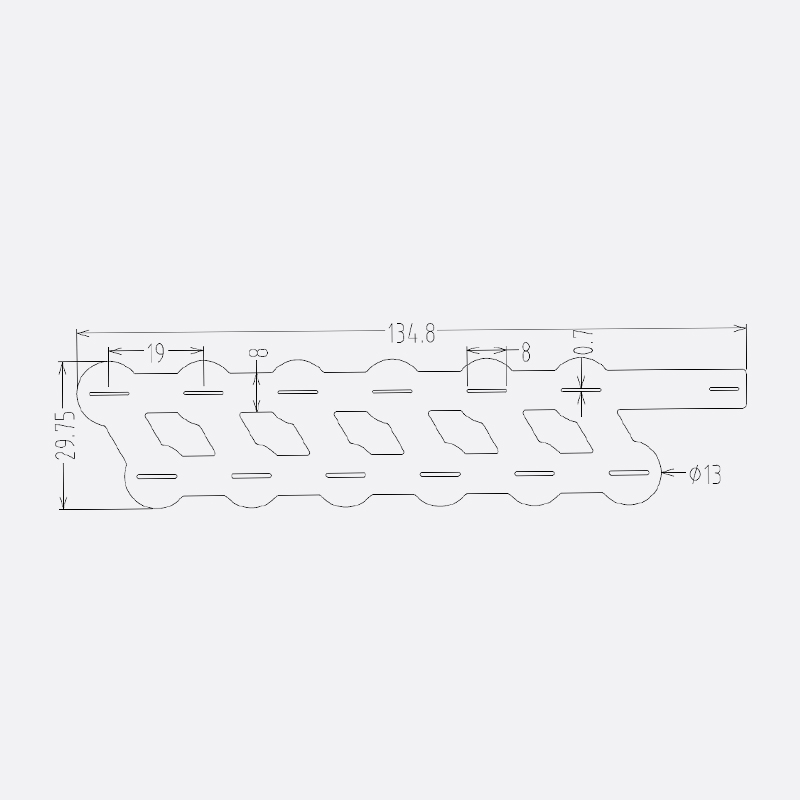

Battery box connector mgmm-4812

4812 Battery Tool-Free Assembly Box Connecting Piece With Copper Plate For E-Bike

-

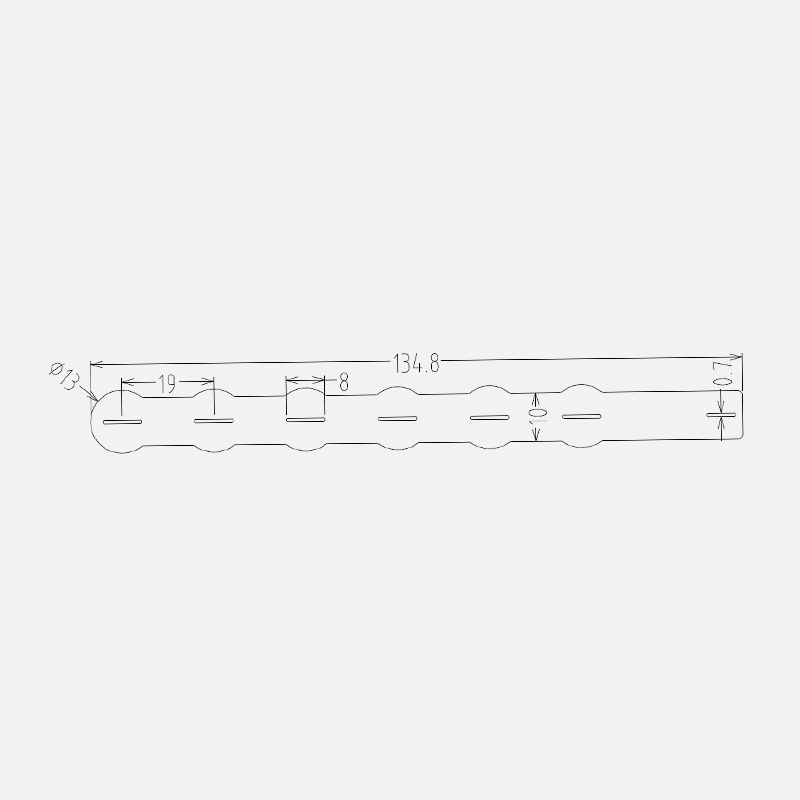

Battery box connector mgmm-4812 LFT-955

4812 Flush Mounting Battery Box Connecting Piece Quick-Release With Copper Plate For E-Bike

-

Battery box bracket for electric bicycles mgmm-4820

RoHS/REACH Compliant mgmm-07 Mesh bracket Battery box for E-bike

-

4828 Battery box bracket for electric bicycles

MGMM-002 High-Strength Mesh Bracket Battery Box For E-Bike

boo@zjmgmm.com / 958587858@qq.com

boo@zjmgmm.com / 958587858@qq.com English

English русский

русский Español

Español عربى

عربى

English

English  Building 33, Demonstration Park, No. 318 Chenguang Road, Eastern New District, Wenling City, Taizhou City, Zhejiang Province, China

Building 33, Demonstration Park, No. 318 Chenguang Road, Eastern New District, Wenling City, Taizhou City, Zhejiang Province, China  0086-576-86337978

0086-576-86337978  0086-576-86333878

0086-576-86333878

boo@zjmgmm.com

boo@zjmgmm.com