Zhejiang Mega Mei Machinery Co., Ltd. is a China Electric Motorcycle Battery Pack Gasket Manufacturer and Sale Electric Motorcycle Battery Pack Gasket Factory. Relying on the driving effect of the Yangtze River Delta Economic Circle and the unique mechanical processing collective advantage of Wenling, Zhejiang Mega Mei Machinery Co., Ltd. specializes in the production of motorcycle and auto parts such as brake lines and accelerator cables. At present, the products produced by the company are exclusively for Honda and other well-known motorcycle manufacturers at home and abroad. Every link from incoming inspection to packaging and shipping is strictly controlled to ensure that every product from Mega Mei Factory can meet the technical requirements of customers, and can pass the QR code source.

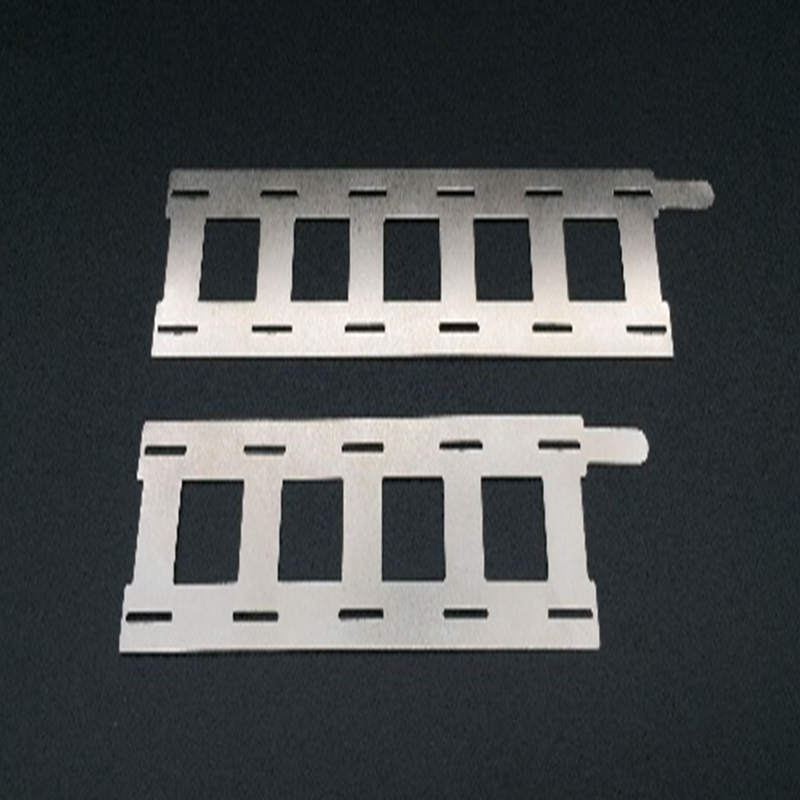

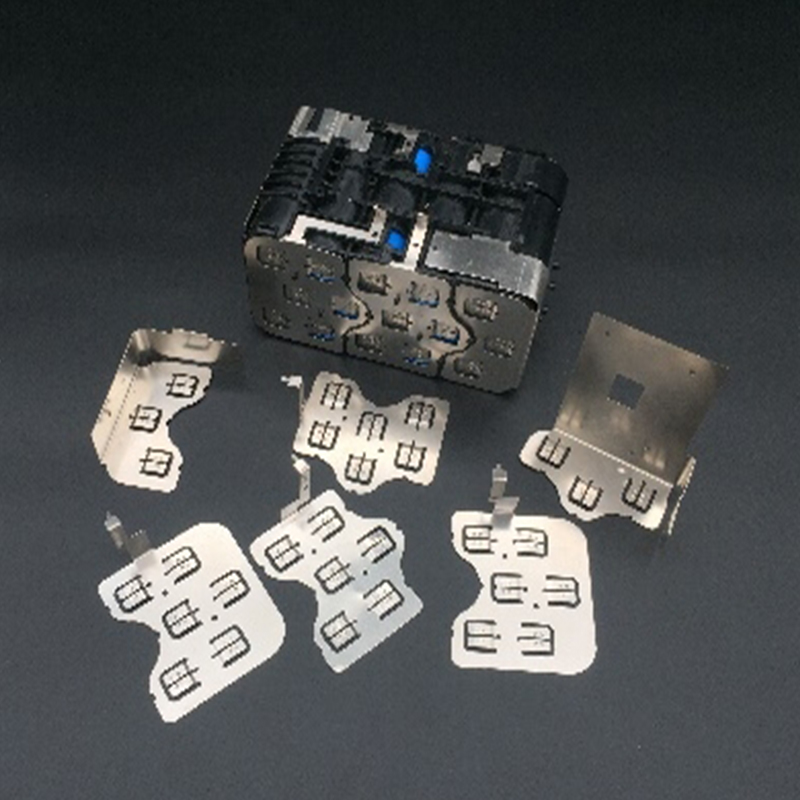

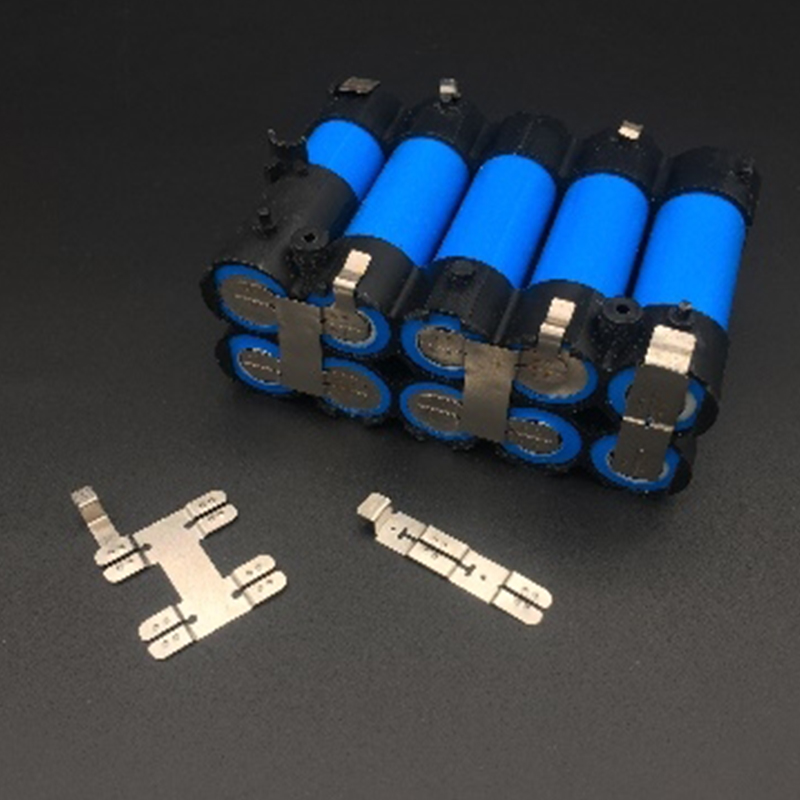

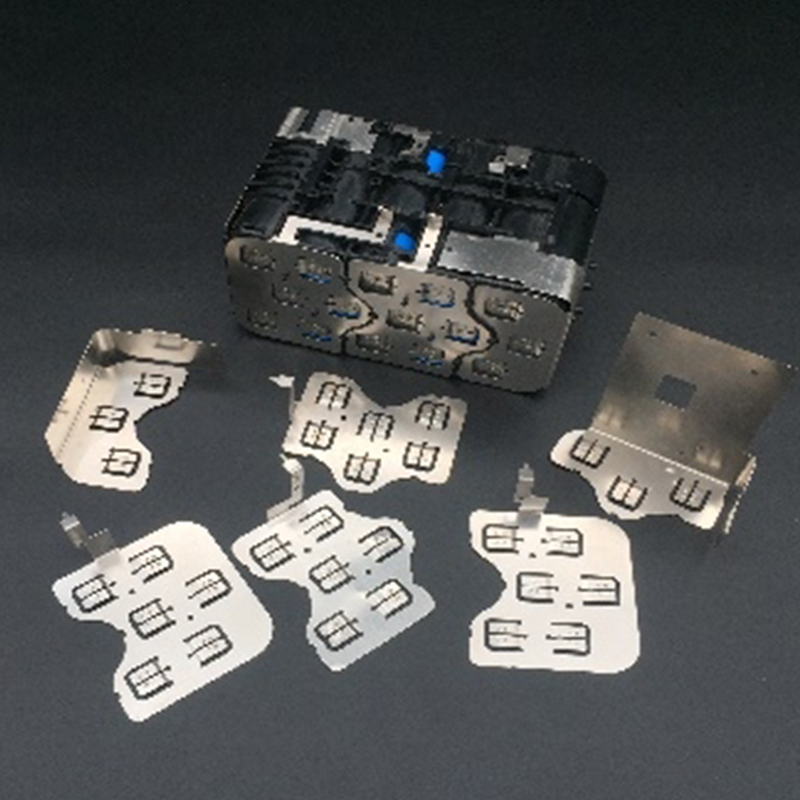

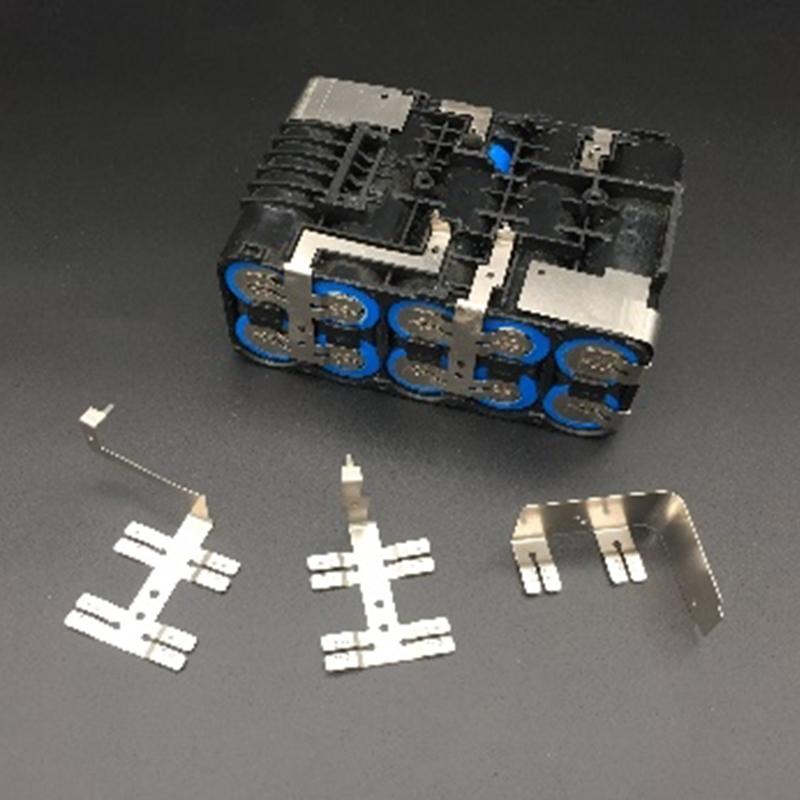

Wholesale Li-Ion Battery Connecting Nickel Plate

Electric Motorcycle Battery Pack Gasket

The Electric Motorcycle Battery Pack Gasket is a crucial component designed to enhance the durability and performance of electric motorcycles. Its primary function is to provide a reliable seal for the battery pack, protecting it from external elements and ensuring the long-term stability of the electric system.

Product Advantages

Enhanced Durability: The gasket is designed to withstand extreme conditions, including high temperatures and vibrations. This ensures the battery pack is protected over an extended period, even in demanding environments.

Improved Battery Life: By offering a robust seal, the gasket helps prevent moisture, dust, and contaminants from entering the battery pack. This contributes to better performance and longer battery life, reducing the need for frequent replacements.

Cost Efficiency: A durable and reliable gasket can reduce maintenance costs over time. By providing an effective barrier against environmental factors, it helps prevent damage to the internal components of the battery, which might otherwise lead to costly repairs.

Easy Installation: The gasket is designed to be user-friendly, making installation quick and straightforward. This minimizes downtime and ensures the battery pack is ready for use without unnecessary delays.

Product Features

High-Quality Material: The gasket is made from advanced materials like silicone or rubber, offering excellent resistance to heat, moisture, and chemicals. This makes it suitable for various environments, including wet and high-temperature conditions.

Precision Engineering: Manufactured with high accuracy, the gasket provides a perfect fit for the battery pack. Its tight seal ensures that there are no gaps, which could potentially lead to leaks or external damage to the battery.

Weather Resistance: The gasket is built to withstand a wide range of weather conditions. Whether exposed to rain, humidity, or direct sunlight, it retains its form and effectiveness, ensuring consistent performance in all weather types.

Shock Absorption: In addition to sealing, the gasket helps absorb some of the shocks and vibrations that occur during riding. This protects the internal components of the battery pack and enhances the overall stability of the system.

-

Threaded long screw rods are widely used in motor-driven applications, including linear actuators, p...

READ MORE -

In the world of battery technology, particularly in electric vehicles (EVs) and energy storage syste...

READ MORE -

Compared with other lithium-ion chemistries, such as NMC (nickel manganese cobalt) or LCO (lithium c...

READ MORE -

The evolution of eBikes (electric bicycles) has transformed cycling into a more accessible and enjoy...

READ MORE -

What are the key advantages of LiFePO4 chemistry compared to traditional lead-acid batteries for a 1...

READ MORE

What precautions should be taken when using Nickel Strip Sheet for Lithium Batteries?

Nickel strip sheets are important for building safe and efficient lithium battery packs. To use them correctly, several precautions should be considered.

Proper Thickness and Width

The nickel strip must match the current requirements of the battery pack.

Strips that are too thin increase resistance and can overheat during high current discharge.

Strips that are too thick are difficult to weld properly and may not improve performance relative to their cost.

Selecting the correct dimensions ensures stable conductivity and minimizes energy loss.

Welding Quality and Technique

Spot welding is the common method to connect nickel strips to battery terminals.

Proper control of welding power, time, and pressure is needed to avoid damaging the battery cell surface.

Weak welds can create loose joints, poor current flow and possible overheating.

Consistent and even welds across all connections improve reliability and reduce long-term failures.

Material Purity

Pure nickel strips are more conductive and corrosion resistant compared to nickel-plated steel.

Nickel-plated strips may wear faster and compromise electrical performance over time.

Verifying material quality through reliable suppliers reduces risks of using low-grade components.

High-purity materials extend battery life and improve overall pack efficiency.

By following these precautions, users can achieve better durability, stronger connections, and safer battery operation.

What is the service life of a Li-Ion Battery Connecting Nickel Plate?

Nickel plates used in lithium-ion battery packs are designed to last as long as the battery itself, but their service life is influenced by several conditions.

Material Durability

- Pure nickel has corrosion resistance, allowing it to remain stable for many years.

- Exposure to moisture, salty air, or corrosive chemicals may still cause gradual degradation.

- Using protective coatings or housing can extend life in harsher environments.

- In normal conditions, nickel plates can last the full lifespan of the lithium-ion cells.

Thermal and Mechanical Stress

- Batteries heat up during charging and discharging cycles, subjecting nickel plates to repeated expansion.

- If heat is not controlled, plates may fatigue and lose conductivity.

- Heavy current loads increase the risk of overheating, which shortens service life.

- Good ventilation and proper design reduce thermal stress, preserving plate stability.

Welding Stability

- Strong welds keep nickel plates firmly attached to the cell terminals.

- Poor or uneven welds may loosen over time, creating high-resistance spots.

- Consistent welding ensures plates function throughout thousands of charge cycles.

- A well-installed plate often outlasts the cells, proving the importance of connection quality.

With high-quality material, proper installation, and controlled conditions, nickel plates can perform reliably for the full cycle life of lithium-ion batteries.

What is the surface treatment process for Battery Spot Welding Nickel Sheet?

The surface treatment process for nickel sheets can be divided into two main stages: preparation and coating.

Preparation and Cleaning

Initial Cleaning

Raw nickel sheets may have oils, dust, or oxidation that affect conductivity.

Cleaning methods include degreasing, ultrasonic washing, or mild chemical baths.

Removing contaminants ensures stronger and more reliable welds.

Surface Smoothing

Sheets are sometimes brushed or polished to eliminate irregularities.

A smoother surface improves welding contact and reduces resistance.

Consistency in thickness also helps in achieving uniform current distribution.

Oxide Removal

Any existing oxidation is treated before welding.

This prevents weak spots during electrical contact.

Clean, oxide-free sheets are easier to process and deliver better conductivity.

Coating and Protection

Corrosion-Resistant Coating

Some nickel sheets receive electroplating or passivation to resist rust.

This ensures long-term performance in environments exposed to moisture.

Heat Treatment and Annealing

Controlled heat treatment may be applied to improve flexibility.

Annealed nickel sheets are easier to handle and weld without cracking.

Final Packaging and Storage

Sheets are stored in dry, controlled conditions to prevent contamination.

Proper packaging maintains quality until they are ready for assembly.

Through preparation and protective coatings, nickel sheets achieve better weldability, longer durability, and more consistent battery pack performance.

boo@zjmgmm.com / 958587858@qq.com

boo@zjmgmm.com / 958587858@qq.com English

English русский

русский Español

Español عربى

عربى

English

English  Building 33, Demonstration Park, No. 318 Chenguang Road, Eastern New District, Wenling City, Taizhou City, Zhejiang Province, China

Building 33, Demonstration Park, No. 318 Chenguang Road, Eastern New District, Wenling City, Taizhou City, Zhejiang Province, China  0086-576-86337978

0086-576-86337978  0086-576-86333878

0086-576-86333878

boo@zjmgmm.com

boo@zjmgmm.com